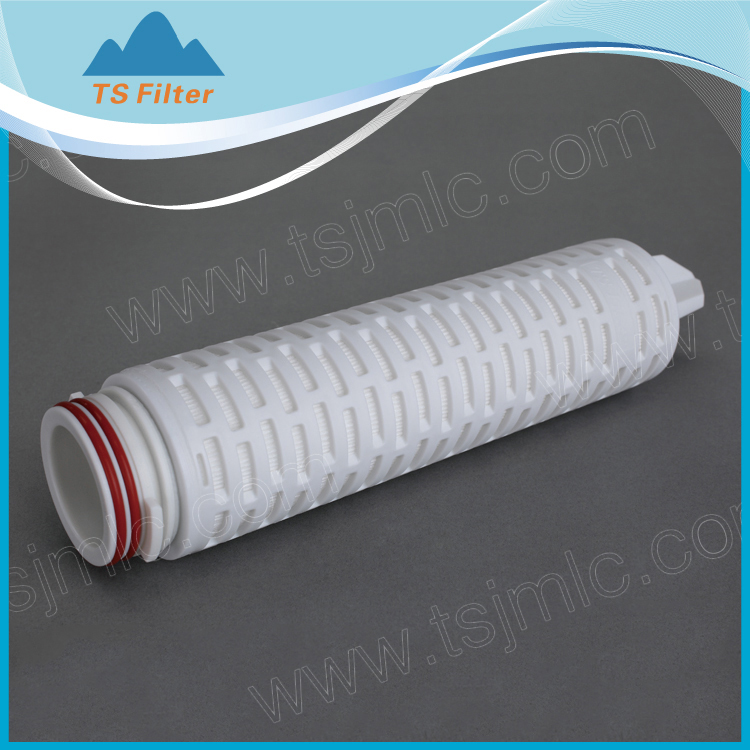

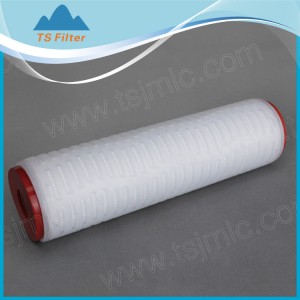

Chinese Professional Factory Price 0.2 Micron Hydrophobic PTFE Air Filter Replacement Sterilizing Air Filter for Food

With trustworthy excellent method, very good standing and excellent client provider, the series of items produced by our firm are exported to many countries and regions for Chinese Professional Factory Price 0.2 Micron Hydrophobic PTFE Air Filter Replacement Sterilizing Air Filter for Food, We have now a big inventory to fulfill our customer’s calls for and needs.

With trustworthy excellent method, very good standing and excellent client provider, the series of items produced by our firm are exported to many countries and regions for High efficient air impurities intercept Hydrophobic PTFE air filter cartridge, We now have a experienced sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalised service and unique goods.

◆Naturally hydrophobic PTFE membrane with excellent porosity, high low rate

◆Absolute rating, filtration efficiency ≥99.99%, Up to 0.01 micron in gas sterile

◆Low pressure drop and long service life

◆Wide chemical compatibility, resistant to strong alkali, acids, aggressive gases and solvents

◆High temperature endurance performance

◆100% integrity tested before final assembly

◆Replace Sartorius ,Pall or Millipore Filter is available

•Compressed air, CO2 line sterile filtration;

•Tank vent, Fermentation air,

•Air filtration in aseptic packaging.

•Aggressive acids, Bases, Solvents;

•Photoresists, Etch Solutions;

Table : Typical water flow rate (10″)

| Materials Of Construction | Filter Media: | Hydrophobic PTFE membrane | ||||

| Support Layers: | Polypropylene | |||||

| Micron Rating: | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um | |||||

| Inner core: | Reinforced Polypropylene/Stainless Steel | |||||

| Outer Cage: | Reinforced Polypropylene | |||||

| End caps: | Polypropylene / Stainless Steel Insert | |||||

| Seal Method: | Thermal Bonded, No Adhesives | |||||

| O-rings/gaskets: | Silicone, Nitrile, EPDM, Viton, Teflon, etc | |||||

| Cartridge Dimensions | Outer Diameter | 69mm(2.75”) | ||||

| Inner Diameter | 33mm(1.30”) | |||||

| Length(based on DOE end caps) | 10″- 254mm, 20″- 508mm, 30″-762 mm, 40″- 1016mm | |||||

| Filtration Area(m2) | 0.65 m2 per 10” | |||||

| Operating conditions | Normal Operating Temperature: | Up to 65℃ (140℉) | ||||

| Max.Operating Temperature.: | 90℃ (194℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.2 bar (60 psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.1 bar (30psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-14 | |||||

| Sterilization: | Steam Sterilization for 30 minutes at 121±2 ℃, 100 cycles, Autoclave 30minutes (optional) |

|||||

| Cartridge Safety | Endotoxin: | <0.25 EU/ml | ||||

| Extractables: | 0.03g / 10″ | |||||

| GRADE | PRODUCT | MICRON | ADAPTER | LENGTH | O-RING / GASKET | |

| P-PHARMACEUTICAL | IPF | 010-0.1um | AA- DOE | 10-10″ | S-silicone; N-nitrile | |

| F- FOOD & BEVERAGE | 020-0.2um | CN-226/FIN | 20-20″ | E-epdm ; T-teflon (encaptulated) | ||

| 045-0.45um | BN-222/FIN | 30-30″ | V-viton | |||

| BF-222/ FLAT SEAL | 40-40″ | How to Order?- Example | ||||

| CF-226/FLAT SEAL | 05-5″ | Pharmaceutical grade; Micron:0.45um; Length:10″ ADAPTER: DOE; Gakset: Silicone. Selection Code is: PIPF045AA10S | ||||

| EN-222 three locking ears /Fin | Other-XX | |||||

With trustworthy excellent method, very good standing and excellent client provider, the series of items produced by our firm are exported to many countries and regions for Chinese Professional Factory Price 0.2 Micron Hydrophobic PTFE Air Filter Replacement Sterilizing Air Filter for Food, We have now a big inventory to fulfill our customer’s calls for and needs.

High efficient air impurities intercept Hydrophobic PTFE air filter cartridge, We now have a experienced sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalised service and unique goods.